Metallurgical Quality

Control

Laboratory Section

- Microstructure analysis for grain structure, case depth, grain size, assessment of heat treatment, inter granular and trans granular corrosion, identification of brittle base, carbide precipitation, inclusion ratings.

- Macro structure for identification of macro defects as inclusions, segregations, dendrites etc.

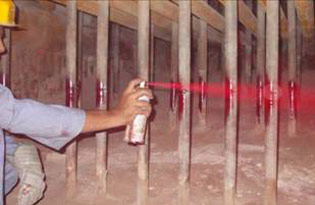

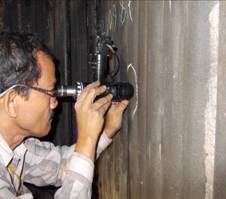

- In situ metallography for metallographic work at site for large heat-treated parts, pipes, fired heater tubes, superheater tubes of boilers, boiler tubes, economiser tubes of boilers, welded parts, boiler plate, hot plate, forged & rolled stocks.

- Scanning Electron Micrography.